SOLAR / BOILER / HEAT PUMP SPARES

All Brands solar water Heater Spares:

Anode/Heating Element (3kw-120kw)/Safety Valve/Gauges/Anode

All Brands Gas Boiler Spares:

Burner/Burner Controller/Gas Valve/Ignitor/Ignition Transformer/Pressure Switch

All Brands Heat Pump/Chiller Spares:

Expansion Valve/Refrigerant/Pressure Transducer/Flow Switch/Ignition Transformer/Pressure Switch

HVAC – ENERGY VALVES/PICV

FUNCTIONING

PRESSURE INDEPENDENT CONTROL: The flow rate is automatically maintained constant at the setpoint value through the modulation of the valve according to the instantaneous value read by the flowmeter.

AUTOMATIC REGULATION OF ΔT: If the ΔT between flow and return is lower than the setpoint value, the flow rate is decreased for achieving the requested value.

CONTROL OF POWER OUTPUT: The flow rate is adjusted for maintaining the thermal power constant at the setpoint value.

ENERGY CALCULATION: By reading ΔT and flow rate, MODFLOW HYDRONIC KIT can calculate and store the thermal energy transferred to the utility.

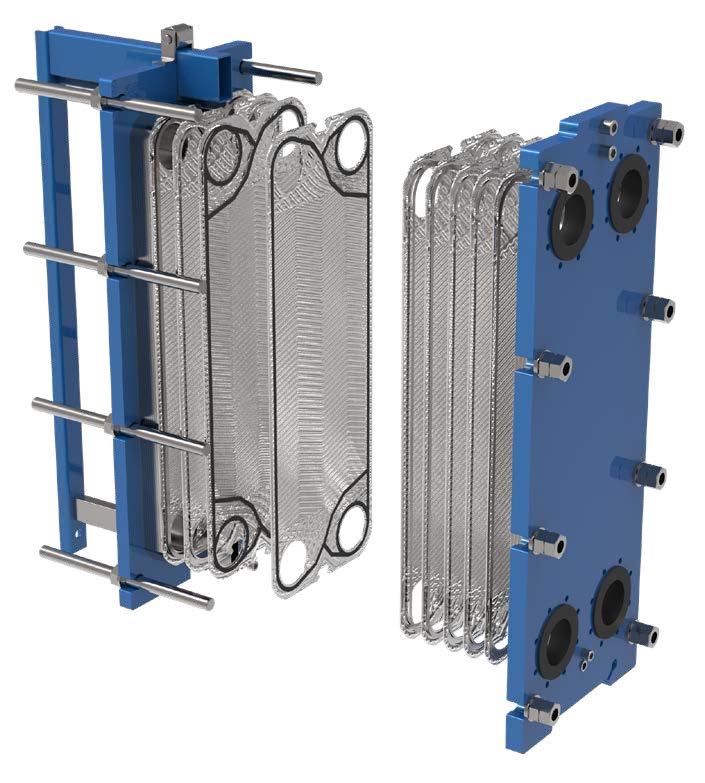

HEAT EXCHANGER

Description:

Plate heat exchangers are designed to ease access and main-tenance. Furthermore, its modularity allows to increase number of the plates according to the heat exchange requirements.

Application:

- DHW production

- heat exchanging in heating systems

- teleheating

- pool water heating

- solar power systems

- heating/cooling of alimentary fluids (milk, beer, wine…)

- cooling of machines

- recuperation of heat from industrial processes

- hydraulics

DIGITAL MIXING / THERMOSTATIC MIXING VALVE +/-1C PRECISION – EUROPE/US

Temperature control – Green Thermal Me provides accurate control of domestic hot water system ensuring all branches of the system are at the desired temperature. Bacteria elimination – By continuously monitoring the temperature of the mixed outlet, hot water tanks and coils can be stored safely at elevated temperatures preventing the growth of bacteria.

Application:

- Apartment Houses

- Schools and Dormitories

- Office Buildings

- Hotels

- Nursing Homes

- DHW Solar Systems

- Modbus communication standard, easy integration to BMS systems

- ASSE 1017 and NSF 372 Listed

HOT WATER BALANCING STATION

Units supports hydraulic balancing of DHW. All you need is set as an controller. The unit is fully automatic controlled based on the requirements Thanks to the newest pump technology from Grundfos/Wilo. The pumps are used in heating circuits with the nominal diameters DN 25 and DN 32 & DN 40.

Features

- No worry about balancing of system

- Quick hot water to the end point with minimized delay

- Easy to fit on wall or in ceiling for retrofit job

ACTUATOR VALVES

USES & FEATURES

- Valves play a crucial role in almost all industrial processes. Used to regulate, redirect, or control the flow of liquids by opening, closing, or partially blocking flow passages.

- Type: 2 way/3Way/Mixing

- Material: SS, Cast iron, PVC

- Actuator: Electric or Pneumatic.

- Control: Wire/Wireless/MODBUS

- Protection Class – IP 65/68

- Available Sizes: DN15 to DN250

HOT WATER STATION / HEATING STATION MODULE

We offers hot water module for domestic water heating.Domestic water heating up to 60˚C.

Advantages of using module

- No Hot water storage tank required – Only buffer required

- No worry about balancing of system

- Saving on hot water storage tank

- Quick hot water to the end point without delay

- Not required to store hot water. Hot water is heated when its required.

DEGASSING/PRESSURISATION UNIT

Foreign particles and substances can significantly reduce the performance and service life of heating systems and increase service intervals. Our solutions can help to prevent this and achieve optimum operating conditions.

Our separation technology uses mechanical separation processes, for which no auxiliary energy is needed. It produces models for dirt and sludge as well as for micro-bubbles and free air. The separation includes micro-bubbles, air bubbles and free air, particularly during filling and draining processes.

- Operating Pressure 10 bar

- Test Pressure 13 bar

- Maximum Operating Temperature 110ºC

- Pressure Class PN16